What is DIN? Everything you need to know about the connective standard

Norms are an integral part of our everyday lives, even if we don't realize it. One such standard is DIN, which plays an important role in the manufacturing industry, especially in the field of fasteners such as screws, nuts and other fasteners. What exactly is DIN and what does it mean? Let's investigate this.

What is DIN?

DIN is an abbreviation of Deutsches Institut für Normung, which in Polish means the German Institute for Standardization. It is a German organization responsible for developing and publishing technical standards for various industrial sectors. DIN standards are widely used in many countries around the world and their purpose is to standardize production processes and ensure interoperability between different systems.

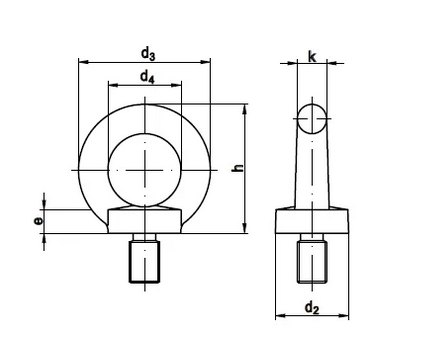

In the context of fasteners, DIN standards include specifications for dimensions, tolerances, materials and other technical parameters for screws, nuts, threads, screwdrivers and many other similar components. Thanks to this, manufacturers can ensure the consistency and quality of their products, and users can be sure that fasteners meet certain standards.

The importance of the DIN standard

DIN standards are crucial to a variety of industries, especially those that use fasteners in their products or manufacturing processes. Here are some reasons why DIN standards are important:

- Quality and consistency: DIN standards define detailed requirements for the quality and technical parameters of fasteners, which help ensure consistency and quality of products.

- Interoperability: Thanks to the use of DIN standards, fasteners from different manufacturers are usually mutually compatible, which facilitates repairs, maintenance and replacement of parts.

- Security: By specifying requirements for materials and strength, DIN standards contribute to ensuring user safety, especially for applications in industries requiring high reliability, such as automotive and aerospace.

- Easier to manage: DIN standards facilitate management and quality control in manufacturing processes because they define clear guidelines for the design, production and testing of fasteners.

Summary

DIN standards play an important role in the manufacturing industry, especially when it comes to fasteners. Thanks to them, manufacturers can ensure high quality and consistency of their products, and users can be sure that the fasteners used meet certain standards. In this way, DIN standards contribute to efficiency, safety and interoperability in many industrial fields.